Doseuro is a combination of two capabilities, the first is a technical expertise gained from many years of experience in the chemical dosing field. The second is a commercial understanding of the changes in this field and a sensitivity beyond the requirements of our customers.

The continuous research and principal effort directed to the customer satisfaction are the fundamental reasons of Doseuro success, which is widely confirmed by the thousand worldwide plants working with our pumps.

Each of our products speaks for itself. High reliability is achieved by constant product development, updating production techniques, constant quality control and rigorous testing at all stages of production.

преглед

Doseuro

Doseuro is a combination of two capabilities: the first is a solid technical knowledge, obtained during a multi-year experience in the dosing field, while the second is a commercial understanding of the changes in this field and sensitivity to our customers’ requirements.

Doseuro chemical dosing pumps are available in three main versions. Plunger pumps with packed plungers, plunger/hydraulic diaphragms or mechanical diaphragms. High pressure pumps are available too, upon request. The range also includes various driving methods, such as electric motor or electromagnetic solenoid operation. The company also manufactures complete dosing packages, electric mixers, and fully automatic plants for the dissolution and mixing of polyelectrolyte, both as powder and emulsion.

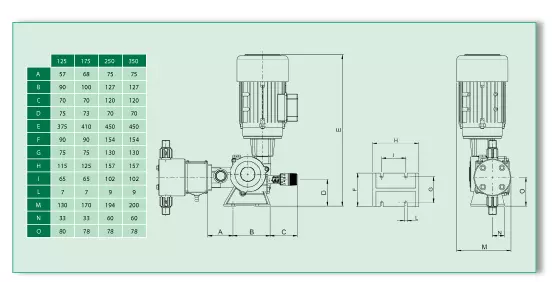

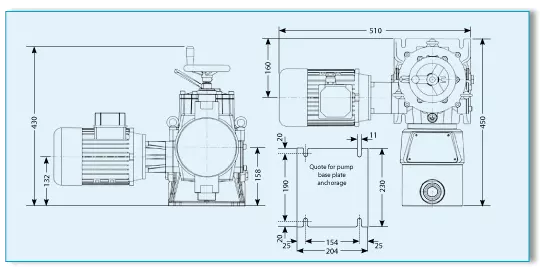

SR Series (type A, D, FM) features:

- Pump head is made from AISI 316 stainless steel or PVC ;

- The standard motor is connected vertically disposed flange B- 14 gear, in accordance with the specification UNEL-MEC;

- Pump capacity is adjusted by micrometer knob, which runs the length of the stroke;

- Optional flow control can be performed by servo (4-20 mA) , or by using an actuator ( a pressure in the range of 0.2 -1.0 bar);

- Pump housing made of cast aluminum , protected with epoxy paint antacid

- Degree of protection: IP55;

- Ability to manufacture explosion proof (ATEX);

- Ability to layout multiple dosing with one motor . Each dispenser can be controlled independently from the other as during operation, and in the idle mode.

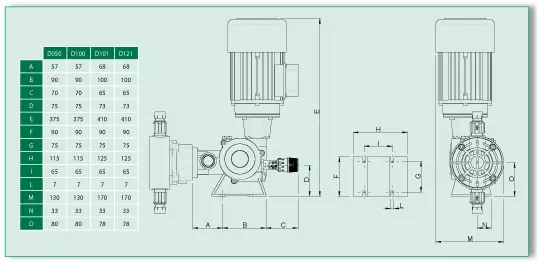

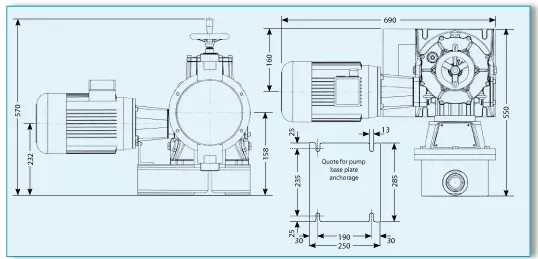

PDP Series features:

- Pumpsare manufactured in accordancewithAPI675;

- The pump head316is made of steelorPVC (polyvinyl chloride). Available on request : Hastelloy, Alloy, PTFE, PVDF, PP.

- Maximum temperature ofthe fluid:90° Cfora headmade ofstainlesssteel and40°C - fora headmade ofPVC.

- The plungerscan be made ofSS316 orceramics.

- Adjustthe stroke length: manually, electrically (forservomotor4-20 mA), a pneumatic motor.

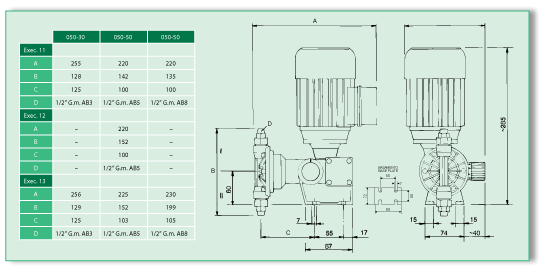

SDP Series features:

- The pump headmay be made ofPP, PVDFor stainlesssteelSS316;

- Outdoorvertical installation;

- The pump housingis made from reinforced polypropylene.