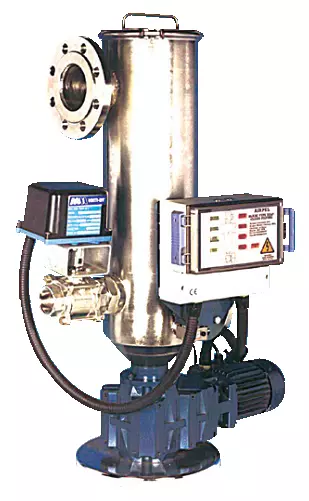

Self-cleaning filters are designed specially to provide efficient filtration for liquids, including those of high viscosity, requiring continuous filtration without interruption to the flow during the cleaning process. There is no operator contact with the process fluid. High quality stainless elements are higly effective in removing contaminant particles as small as 25 micron.

The filter is available for either manual or fully automatic electric or pneumatic operation. The range of optional control devices makes it particularly suitable for continuous processes and for service with high contamination levels.

преглед

Self-cleaning filters

Principle of Operation:

The Airpel Series self-cleaning filter (SCF) blends modern technology with simplicity to provide a versatile method of filtering your process fluids. The filter can be set up for fully or semi-automated or manual operation during which the liquid enters the body and flows through the filter element from outside to in. Debris is collected on the outside of the wedge wire or perforated element. Cleaning takes place without interruption to flow by the rotation of the element against fixed scraper blades. The debris accumulated during rotation is deposited into the bottom of the filter body from where it can be periodically discharged either manually or automatically via the drain port. Ideal for processes that require continuous flow, the SCF range is also suitable for use on unmanned sites and with hazardous process fluids.

Maintaining the product quality by the use of an Airpel Series self cleaning filter, helps to reduce downtime, increase productivity and contain/reclaim unwanted debris to comply with company and environmental legislation

Main industries where product is used:

- Water treatment

- Food and beverage

- Pharmaceutical

- Paints, inks and varnishes, etc.

Основные преимущества:

- No operator contact with liquid during cleaning operation.

- Minimised product loss – during both process production and system cleaning.

- Increased quality output – minimum disruption to product flow.

- Reduced contamination – less possibility of accidents or operator exposure to the fluid.

- Reduced maintenance costs – automated units eliminate manual cleaning.

- Environment friendly – enclosed design with minimal flushing losses.

Automation

The Airpel Series automated self-cleaning filters allows for stand alone, low maintenance processing of liquids. The range can be automated, either electronically or pneumatically, from 32 mm (1.25") and above. The level of automation can be selected from manual cleaning and valve operation to fully automated filters which can be supplied wired and fully tested, requiring only on site connection to the power source and dump valve connection.