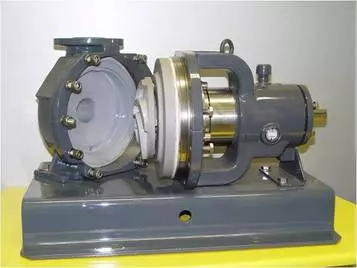

ET - Double mechanical seal chemical process pump

преглед

Lined pumps are becoming more and more popular in the chemical industry. Today the ceramic lined pump is often used successfully in the treatment of difficult slurry applications (e.g. titanium dioxyd).

The ET offers all advantages of our long lasting experience in manufacturing non-metallic pumps, using top quality chemical ceramic for pumping heavy corrosive and abrasive chemicals, e.g. hydrochloric acid, nitric acid, filter dust, sludge, etc.

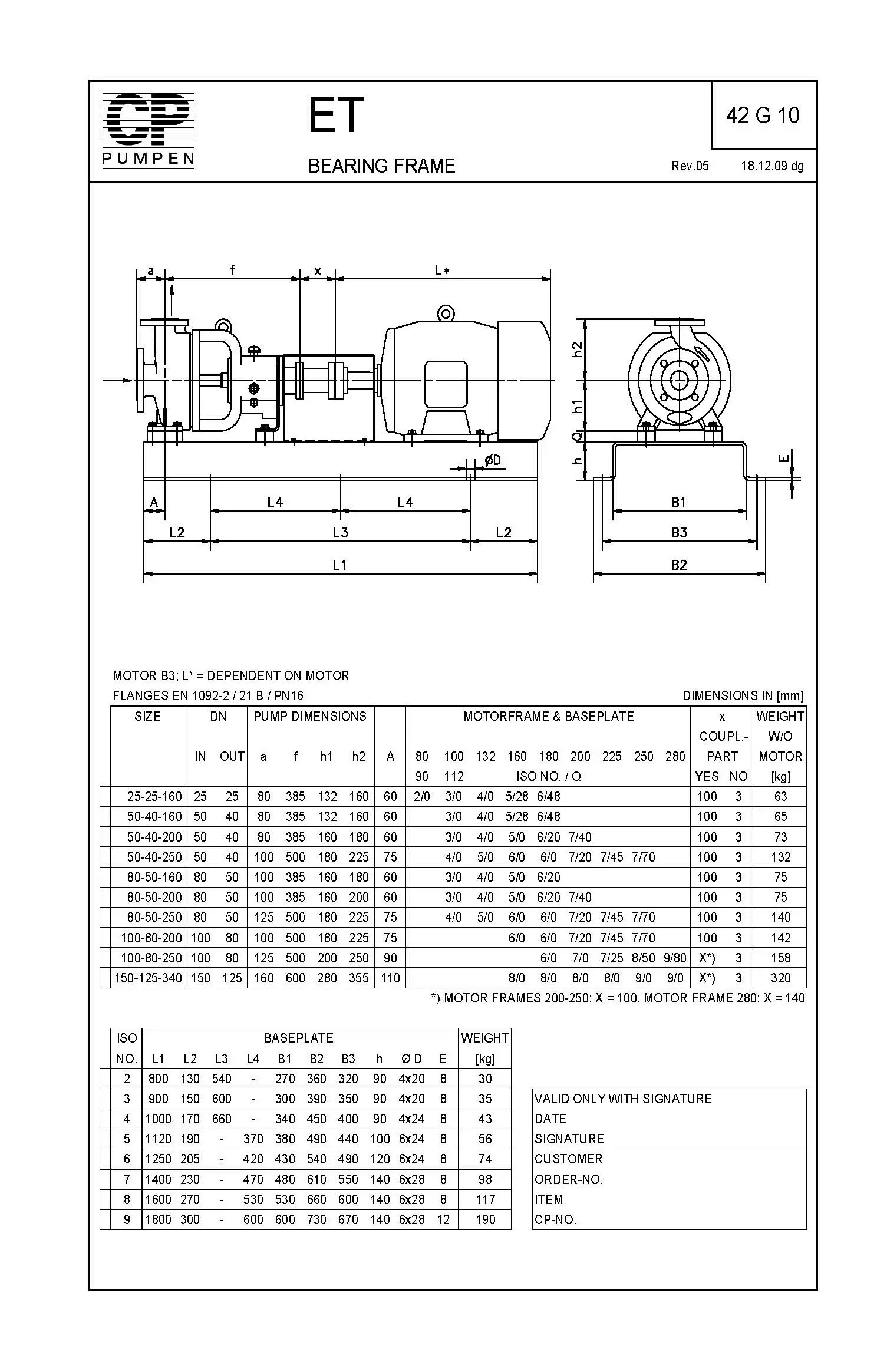

ET series are designed according to ISO 2858, and were developed with optimum efficiencies to meet power saving requirements. Excellent corrosion resistance against all chemicals and mixtures (except for hydrofluoric acid and concentrated alkaline solutions). High strength and heat resistance.

Key features

- Corrosion resistant process pump with metallic body made out of ductile iron (EN-GJS-400-18) and with massive ceramic lining

- Pump is available with different single and double mechanical seal designs

- FuturaMik® mechanical sealing system excellent for pumping liquids with a high solids content

- All inner parts of the pump are metal-free

- Design pressure PN 16 and vacuum resistance up to high temperatures allow a wide application range

- Very robust construction and ceramic-lining anchored on metallic pump casing with high torsional security

- Closed impellers with high efficiency and open impellers with low NPSH-values available

- Manifold accesories for different requirements available

Technical data

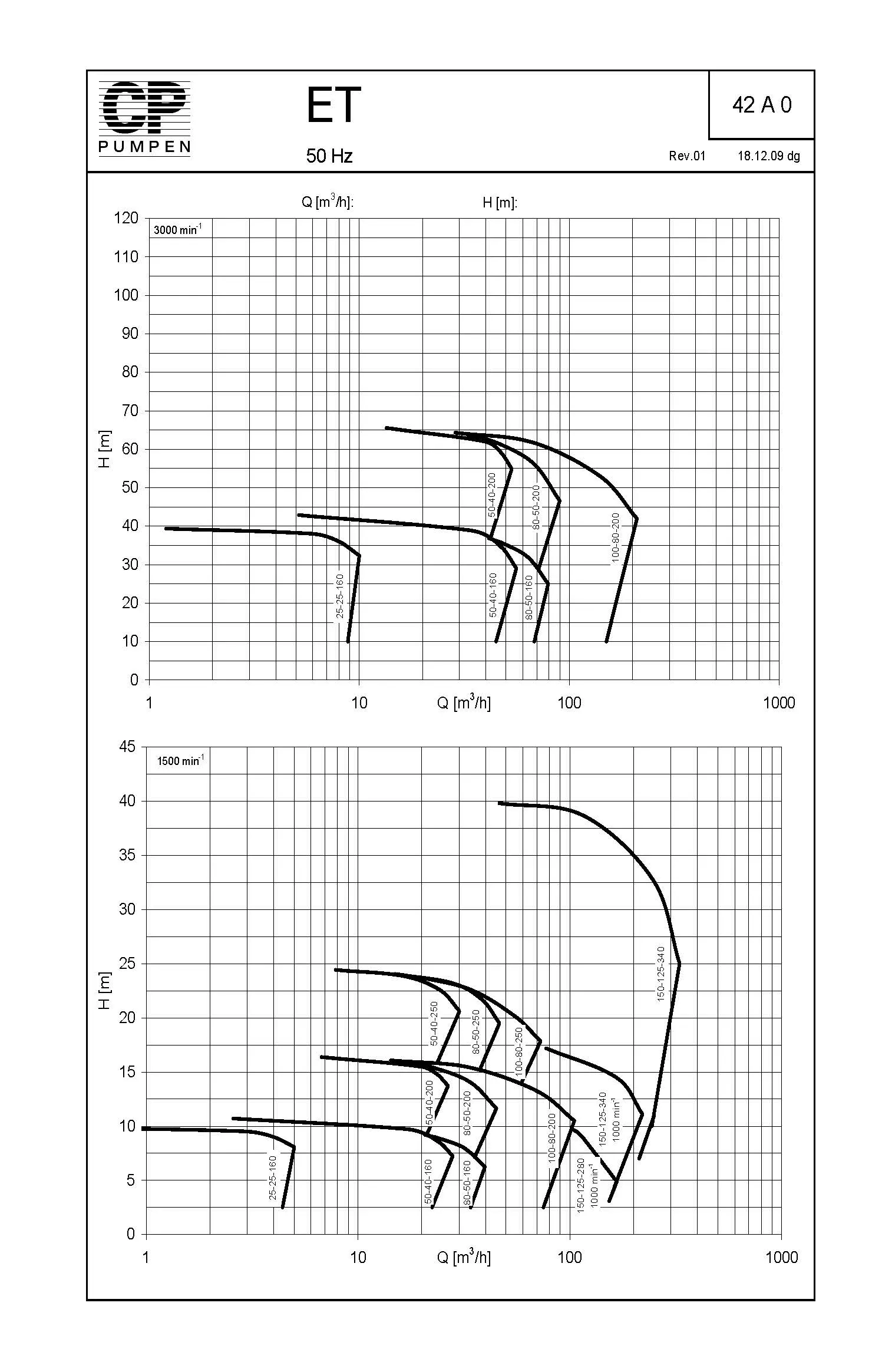

- Capacity range (min.-max.): 0.5 m3/h up to 300 m3/h

- Head range (min.-max.): 3 m up to 70 m

- Temperature range (min.-max.): -20° C up to +150°C

- Nominal pressure: PN10