For 90 years SPX's Lightnin brand has been recognized as the leader in Mixing Technology. Our extensive knowledge base and dedication to continuous product development ensure efficient and reliable plant operations around the world. With our unsurpassed process application experitse, and state of the art analytical design tools we can solve virtually any mixing challenge no matter how complex.

преглед

Industries

Chemical Processing

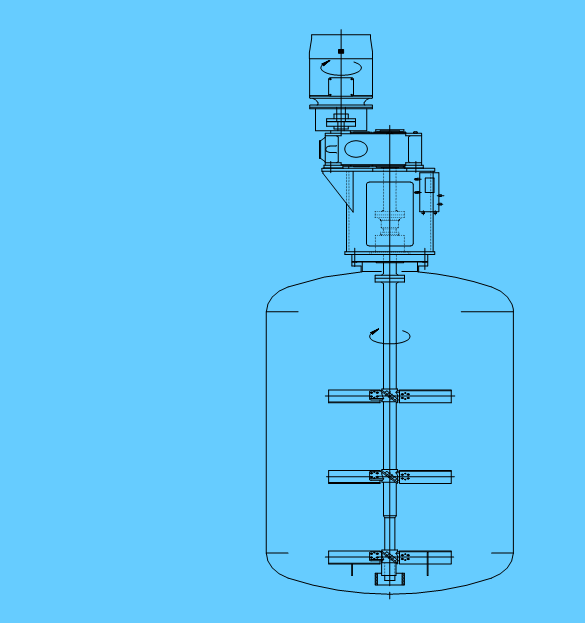

LIGHTNIN Top Entry, Side Entry and Static Mixers are used around the world for a wide variety of applications in the Chemical Processing industries, including:

- blending

- suspending solids

- heat transfer

- solids wet-out

- polymerization

- dissolving

- shearing

- mass transfer

- complex chemical reactions

- hydrogenation

LIGHTNIN mixers are available in sizes from 1/4 to 3500 HP for use in bench scale, pilot scale, semi-works and full-scale operations.

Mining and Minerals

Select Lightnin equipment and you get more than an efficient and cost effective process. You get over 85 years of experience in superior processing technology. This experience has enabled us to design and develop products specifically for minerals processing way into the 21st century.

Areas of application:

- Autoclave and Pressure Oxidation

- Coal Sluries

- Draft Tube Precipitators

- Solvent Extraction

- Clay Slurry

- Attrion Scrubber

- CIP and CIL

- Flotation

- Bottom-Entry Draft Tube Crystalizers

- Biological and Bacterial Oxidation

- Phosphoric Acid

Oil and Petroleum

LIGHTNIN side-entry mixers are used for a variety of blending, mixing and storage applications:

- Asphalt

- Crude Oil

- Gasoline

Slurry Pipelines and Storage

Just about every step in minerals processing recovery depends on suspending solids or a flow stream mixed uniformly with a liquid or gas. We can help you manage the many variables that influence the throughput of your entire process.

Lightnin offers a full family of axial flow impellers for the different levels of solid suspension required for slurry storage.

Water and Wastewater Treatment

LIGHTNIN mixer and impeller systems are used in all stages of municipal and industrial water and wastewater treatment, including:

- rapid mixing

- chemical makeup and storage

- sludge holding and digestion

- equalization and neutralization

- flocculation

- activated carbon slurry mixing

- aeration

- disinfection

LIGHTNIN understands every phase of water and wastewater treatment. We combine this process knowhow with LIGHTNIN mixing technology and the complete range of mixers and impeller designs to optimize your results

Pharmaceutical and Biotechnology

You can find LIGHTNIN mixers at work in cGMP facilities for both upstream and downstream pharmaceutical processes, including:

- vaccine production

- antibiotics

- mammalian cell cultures

- blood factors

- injectables

- buffer solutions

Flue Gas Desulfurization

Lightnin has successfully applied hundreds of Top and Side Entry agitators for flue gas desulfurization processes, from the very first FGD installation in the 1960’s at the Lawrence Energy Center to today’s modern power plants.

Since the first installation, the Boiler Systems have advanced considerably from the multiple Absorber Towers per Boiler in the 1970’s and 80’s to today’s systems with a single tower per Boiler, capable of operation for extended periods without shutdown.

At Lightnin, we bring 90 years of mixing experience to your flue gas desulphurization (FGD) process. We believe that getting the job done right means providing the degree of mixing you need while striking the best balance of capital cost, energy consumption, and reliability.