Технически данни

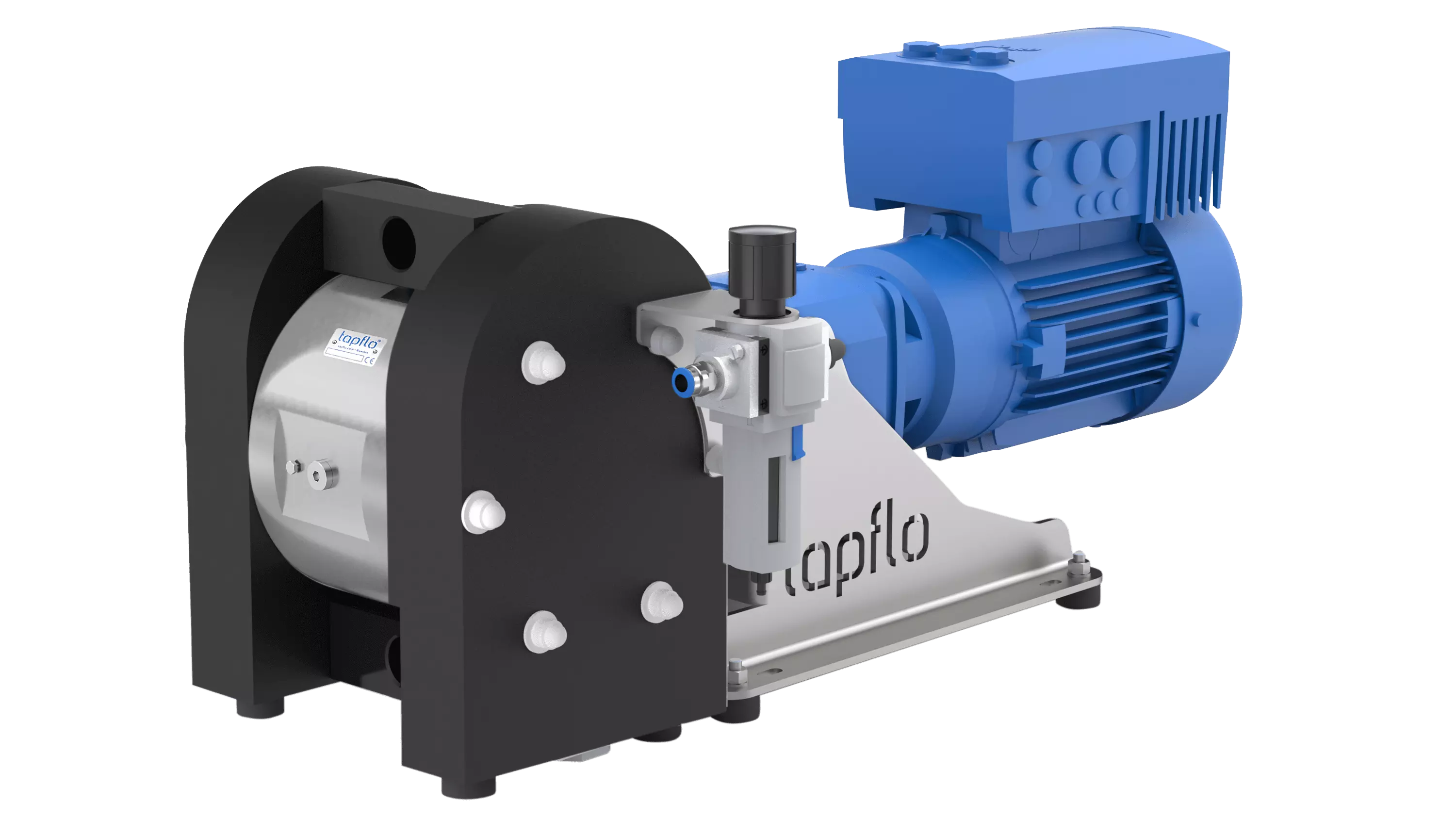

| PE и PTFE | Максимален капацитет (л/мин) |

вход и изход БСП инв. |

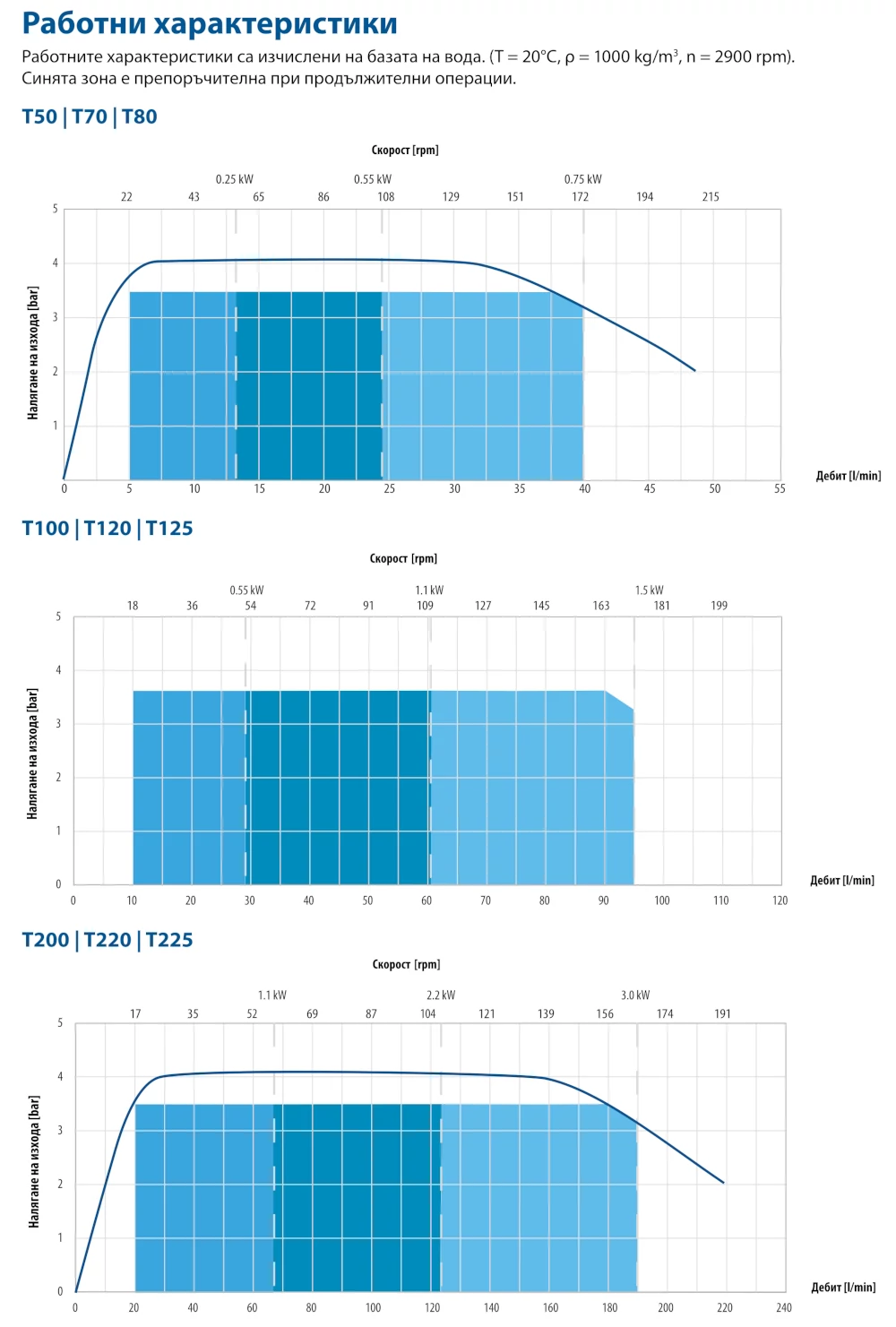

| TE50P | 48 | 1/2" |

| TE100P | 110 | 1" |

| TE200P | 220 | 1 1/2" |

| TE50T | 48 | 1/2" |

| TE100T | 110 | 1" |

| TE200T | 220 | 1 1/2" |

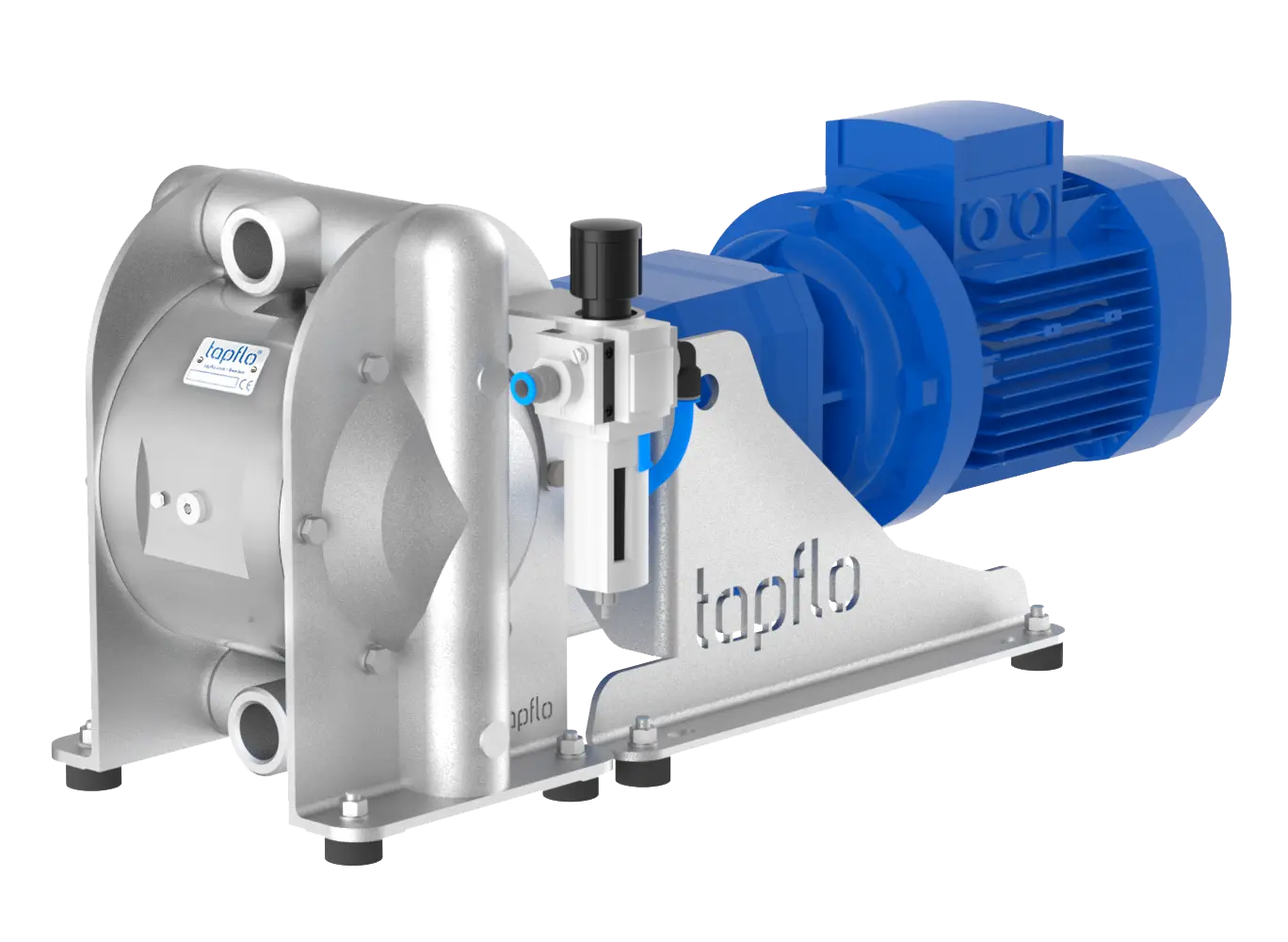

| Метал | Максимален капацитет (л/мин) |

вход и изход БСП инв. |

| TE70S | 48 | 3/4" |

| TE120S | 110 | 1" |

| TE220S | 220 | 1 1/2" |

| TE70A/C | 48 | 3/4" |

| TE120A/C | 110 | 1" |

| TE220A/C | 220 | 1 1/2" |

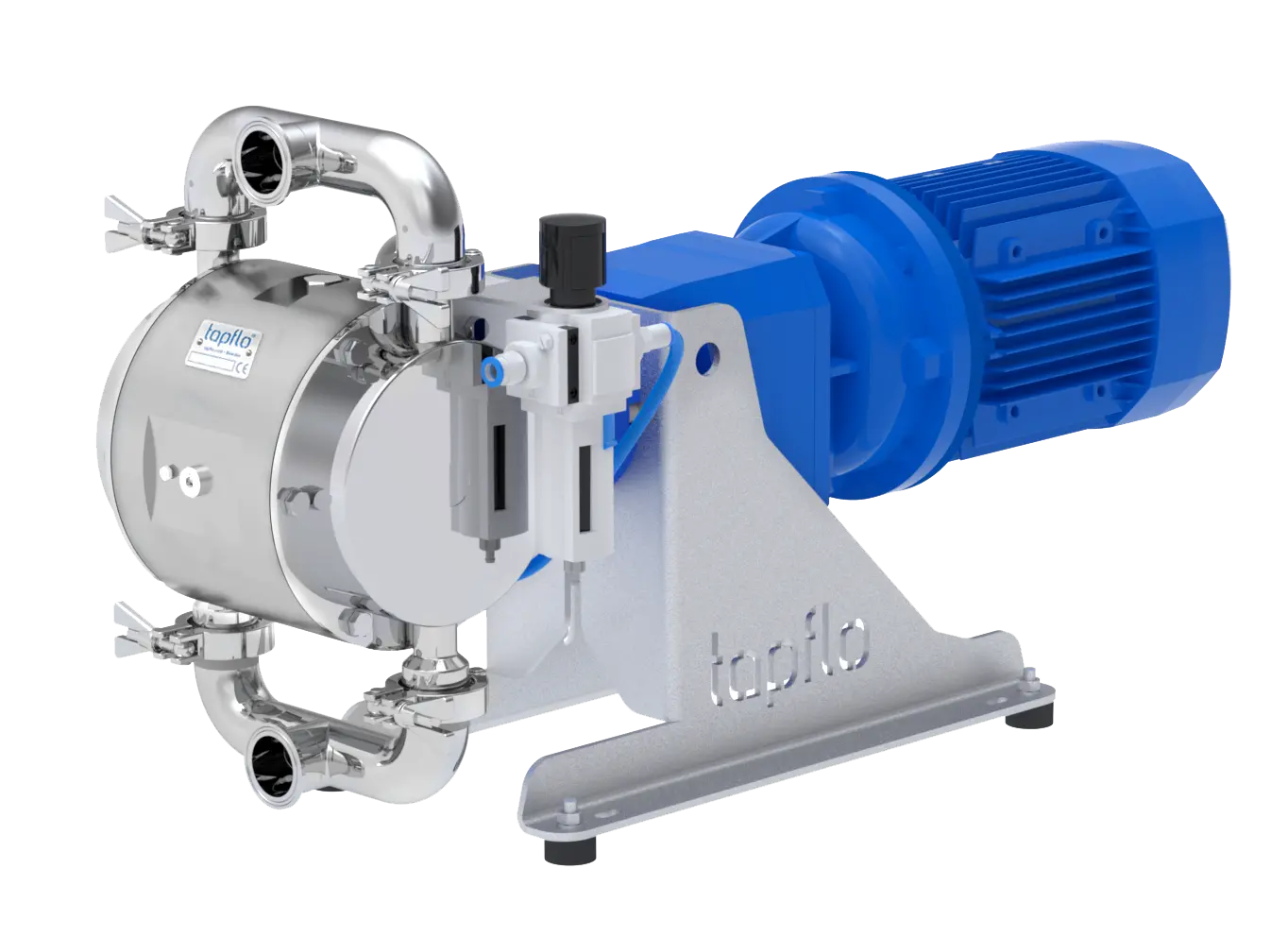

| Санитарен | Максимален капацитет (л/мин) |

вход и изход стандартен |

| TE80 | 48 | DN 25 SMS 3017 tri-clamp |

| TE125 | 110 | DN 38 SMS 3017 tri-clamp |

| TE225 | 220 | DN 51 SMS 3017 tri-clamp |

Широк диапазон от приложения

- Химическа промишленост

- Целулозно-хартиена промишленост

- Обработка на повърхности /Галванизация/

- Санитарни приложения

- Третиране на води

- Машиностроене

- Бояджийска и мастилена промишленост

- Лакова промишленост

Характеристики и предимства

- Нисък разход на енергия. Консумация на електричество < консумация на компресиран въздух, високоефективен електрически двигател (клас IE3)

- Мембрани с дълъг жизнен цикъл. Пневматична и на мембраната поддръжка на мембраната

- Работа на сухо без риск от повреда Лесна за употреба, без от защитно устройство поддръжка необходимост

- Ниска цена на резервни части. Помпата е с почти идентична конструкция откъм омокряемата страна, както на стандартните Tapflo въздушно задвижвани мембранни помпи. Затова повечето резервни части са еднакви.

- Малко компоненти и конструкция с дълъг жизнен цикълНамалено време за принудителен престой и ниски разходи за поддръжка

- Лесна поддръжка Без необходимост от смазване, без риск от протичане

- Самозасмукване.Повече възможности за монтаж